Combined heating and power generation systems (CHP) are becoming increasingly common as a means to provide resilient and high efficiency building environment management. The COMER lab is currently investigating the integration of direct and flame assisted solid oxide fuel cells (SOFCs) into heating, ventilation, and air conditioning (HVAC) systems to produce environmentally friendly and low footprint CHP systems. These systems include residential furnaces, boilers, and heat pumps. Figure 1 illustrates the minimal system alteration required for SOFC integration. All of these systems provide two necessary environmental characteristics. The first is a fuel-rich environment. Fuel cells require simple hydrocarbons and/or carbon monoxide in order to operate. Natural gas and propane are the most commonly used HVAC fuels given their low cost, easy delivery, and wide-scale availability. These fuel can directly be used as fuel for the SOFCs. However, as was seen in the development of direct flame and flame assisted SOFCs, fuel-rich combustion yields syngas-a combination of hydrogen and carbon monoxide-which is a highly effective SOFC fuel. The other requirement for SOFC operation is a high temperature environment. The electrolyte within SOFCs does not become ionically conductive until reaching temperature in the range of 500-1000 degrees Celsius. Luckily, these temperature are present in the combustion chamber of the previously mentioned HVAC equipment as well as the required fuel. Ultimately, this means SOFC integration into furnaces, boilers, and heat pumps is possible and an effective strategy to develop new CHP systems.

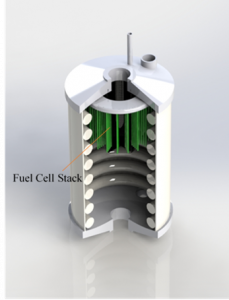

Figure 1: Computed aided design image of boiler combustion chamber with radial burner and green SOFC fuel cell stack inserted.

Figure 1: Computed aided design image of boiler combustion chamber with radial burner and green SOFC fuel cell stack inserted.